|

|

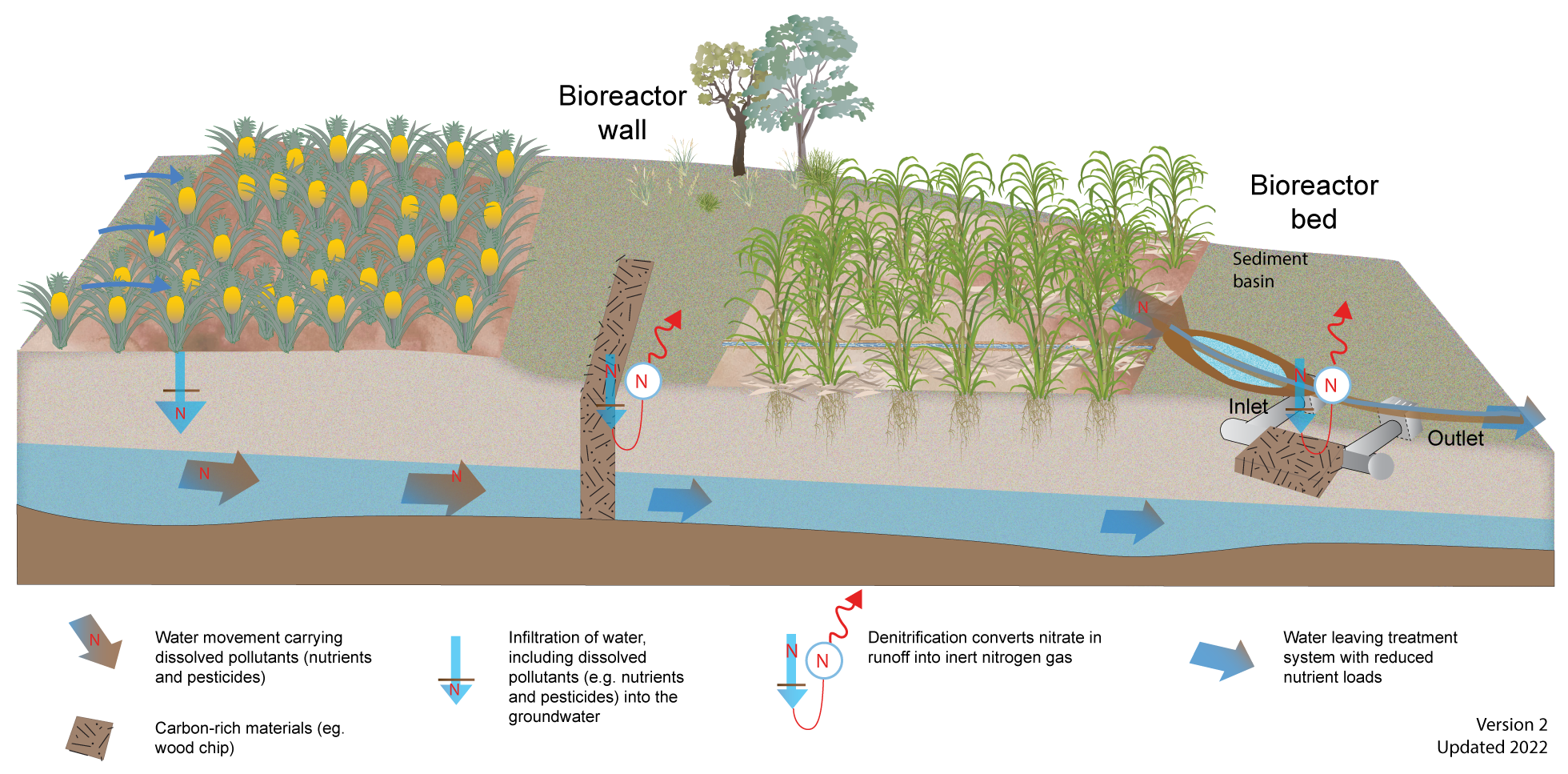

BioreactorsBioreactors — Construction and operationSelect from the tabs below ApprovalsA range of legislation and approvals may be required for the construction of a bioreactor. Contact your local government before any construction is undertaken to understand requirements. Prior to construction, check for any existing infrastructure by contacting electricity, water and telecommunication providers. It is also recommended that local Traditional Owners are engaged to ensure no sites or items of cultural significance are disturbed during excavation. Professional advice should be sought prior to construction to ensure the bioreactor is sized and sited appropriately, considering soil suitability, groundwater and local hydrology. Construction

Timelapse video of a bioreactor bed being built on a cane farm in the lower Burdekin Time for establishmentA bioreactor can be constructed and operational within a few days, depending on the size of the structure and any associated pipe work or structures. Denitrification will commence within hours of nitrate entering the bioreactor. The denitrifying microbes are naturally present in the environment, so no ‘seeding’ is required. OperationOperational requirements are minimal. Bioreactors operate passively. Monitoring and maintenanceTypical monitoring and maintenance of bioreactor beds will involve:

Bioreactor walls require limited maintenance, other than slashing of grass at the surface. Soil may need to be replaced on the top of the bioreactor wall if subsidence or erosion occurs. Monitoring of nitrate entering and leaving the bioreactor will help determine if the bioreactor is effectively removing nitrate as designed. Monitoring regimes for quantifying the nitrate removal performance of bioreactors is outlined in Using denitrifying bioreactors to improve water quality on Queensland Farms. Videos on monitoring bioreactors are also available. Lifespan/replacement timeThe woodchips within the bioreactor bed or wall will gradually degrade over time and hydraulic efficiency will be reduced. Trials in Queensland suggest a 10-12 year lifespan for bioreactors, although this will depend on the woodchips used, site conditions (wetting and drying regime and temperature). After this time the woodchips will need to be replaced, although this should cost less than the original construction, especially for bioreactor beds as the inlet and outlet structures may not need replacing[4]. DisclaimerIn addition to the standard disclaimer located at the bottom of the page, please note the content presented is based on published knowledge of treatment systems. Many of the treatment systems described have not been trialled in different regions or land uses in Queensland. The information will be updated as new trials are conducted and monitored. If you have any additional information on treatment systems or suggestions for additional technologies please contact us using the feedback link at the bottom of this page. References

Last updated: 24 May 2022 This page should be cited as: Department of Environment, Science and Innovation, Queensland (2022) Bioreactors — Construction and operation, WetlandInfo website, accessed 8 May 2025. Available at: https://wetlandinfo.des.qld.gov.au/wetlands/management/treatment-systems/for-agriculture/treatment-sys-nav-page/bioreactors/construction-operation.html |

— Department of the Environment, Tourism, Science and Innovation

— Department of the Environment, Tourism, Science and Innovation