|

|

Recycle pitsRecycle pits — Construction and operationSelect from the tabs below ApprovalsApprovals may be required for the construction of a treatment system. Contact your local government before any construction is undertaken to understand requirements. For example:

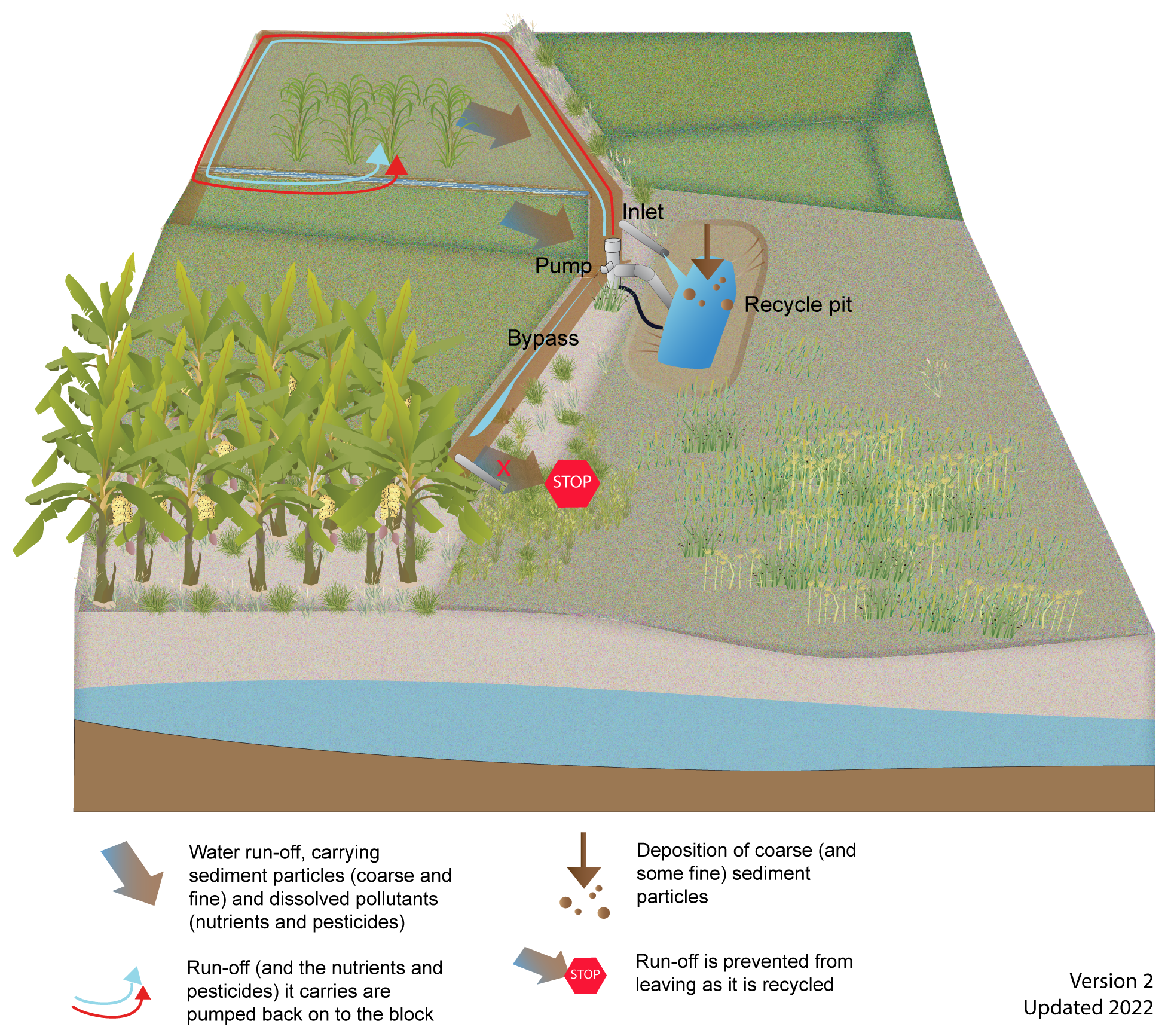

It is also recommended that local Traditional Owners are engaged to ensure no sites or items of cultural significance are disturbed during excavation. Engineering advice should be sought prior to construction to ensure the treatment system is sized and sited appropriately, taking into account soil suitability, groundwater and local hydrology. The stability and safety of the treatment system should also be considered. ConstructionRecycle pits will require earthworks to excavate a pit. The angle of the batters will depend on the soil type, but generally batters should be less than 2.5:1 and no steeper than 3:1.[2]. The upper batters should be stabilised with jute matting or non-invasive grass to prevent erosion. An inlet and outlet into a farm drain also needs to be constructed and can be either an open drain or pipe. Spoil should be reused on the property or deposited away from natural wetlands and waterways and the spoil disposal site should be bunded to avoid sediment loss. Time for establishmentFollowing construction, pipes and pumping infrastructure needs to be installed and connected to the existing irrigation system to enable water to be reused on the farm. A recycle pit can be constructed and operational within a week (will depend on the size of the structure). The batters of a recycle pit should be stabilised with grasses or groundcovers to prevent erosion. Use local guidelines if they are available to assist with plant selection or contact your local Landcare or NRM group. Natural waterways, wetlands and riparian zones are a good reference from which to create a possible species template. See Plant Guides. The establishment of vegetation may require irrigation and weed management until it is fully established, which can take up to two years. Operation

Monitoring and MaintenanceRecycle pits should be inspected every six months, or after every major storm event to ensure the structure and pumping infrastructure has not been compromised. It is recommended that the water in the recycle pit be tested occasionally to ensure that the water being reused on the farm is suitable for the crop and does not have high herbicide concentrations or salinity that may impact crop productivity. Regular water quality monitoring will provide information on nutrient and pesticide losses from the farm and help growers identify the nutrient concentration in the reuse water. Test strips are a quick and cheap way to check the presence of nitrogen. If nitrogen is present in the reuse water then laboratory testing is recommended to accurately determine the concentration. This will enable fertiliser rates (or timing, application etc.) to be modified accordingly to save input costs, without impacting productivity[2]. Maintenace of recycle pits include:

Lifespan/replacement timeWith regular maintenance, particularly to the pumping infrastructure, recycle pits should last indefinitely. DisclaimerIn addition to the standard disclaimer located at the bottom of the page, please note the content presented is based on published knowledge of treatment systems. Many of the treatment systems described have not been trialled in different regions or land uses in Queensland. The information will be updated as new trials are conducted and monitored. If you have any additional information on treatment systems or suggestions for additional technologies please contact us using the feedback link at the bottom of this page. References

Last updated: 10 June 2022 This page should be cited as: Department of Environment, Science and Innovation, Queensland (2022) Recycle pits — Construction and operation, WetlandInfo website, accessed 8 May 2025. Available at: https://wetlandinfo.des.qld.gov.au/wetlands/management/treatment-systems/for-agriculture/treatment-sys-nav-page/recycle-pits/construction-operation.html |

— Department of the Environment, Tourism, Science and Innovation

— Department of the Environment, Tourism, Science and Innovation