|

|

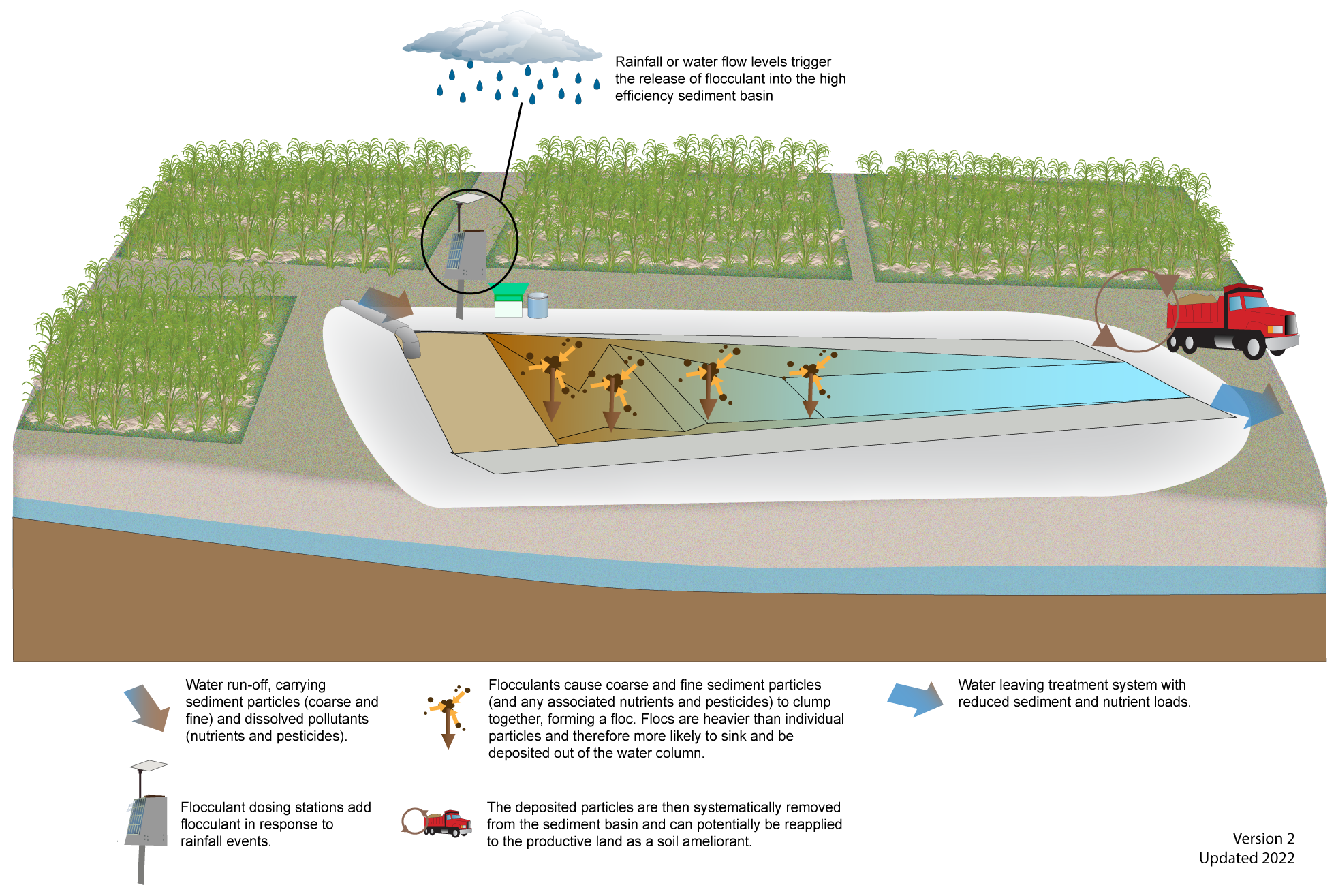

High efficiency sediment basinsHigh efficiency sediment basins — Construction and operationSelect from the tabs below ApprovalsA range of legislation and approvals may be required for the construction of a HES basin. Contact your local government before any construction is undertaken to understand requirements. Prior to construction, check for any existing infrastructure by contacting electricity, water and telecommunication providers. Engineering advice should be sought prior to construction to ensure the basin is sized and sited appropriately, taking into account soil suitability, groundwater and local hydrology. ConstructionHES basins will require earthworks to excavate a pit. The angle of the batters will depend on the soil type, but generally, batters should be less than 2.5:1 and no steeper than 3:1 unless reinforced by stabilising material. The upper batters should be stabilised with jute matting or non-invasive grass to prevent erosion. An inlet and outlet into a farm drain also need to be constructed and can be either an open drain or pipe. Spoil should be returned to the farm, or disposed of away from natural wetlands and waterways (Subject to ensuring that the aluminium content of the material and other factors are acceptable for agricultural use). The spoil disposal site should be bunded to avoid sediment loss. EstablishmentAn HES basin can be constructed and operational within a month of construction (will depend on the size of the structure). OperationOperation of an HES basin requires:

MaintenanceTypical maintenance will involve:

MonitoringBasins should be inspected regularly and after every major rain event to ensure the structure and pumping infrastructure has not been compromised. Lifespan/replacement time10 year replacement of coagulant dispensers. 20 year re-set of basin to original design. DisclaimerIn addition to the standard disclaimer located at the bottom of the page, please note the content presented is based on published knowledge of treatment systems. Many of the treatment systems described have not been trialled in different regions or land uses in Queensland. The information will be updated as new trials are conducted and monitored. If you have any additional information on treatment systems or suggestions for additional technologies please contact us using the feedback link at the bottom of this page. Last updated: 10 June 2022 This page should be cited as: Department of Environment, Science and Innovation, Queensland (2022) High efficiency sediment basins — Construction and operation, WetlandInfo website, accessed 8 May 2025. Available at: https://wetlandinfo.des.qld.gov.au/wetlands/management/treatment-systems/for-agriculture/treatment-sys-nav-page/high-efficiency-sediment-basins/construction-operation.html |

— Department of the Environment, Tourism, Science and Innovation

— Department of the Environment, Tourism, Science and Innovation